Quick Release One Touch Fasteners for Quick Changeover

Reduce setup times with quick and easy tool-less clamping

One Touch Fasteners provide fast, secure locking and unlocking for fixture plates, panels, covers, machine components, and more.

Simply turn the knob or push the button to lock, eliminating the need for tightening screws.

These quick and easy tool-less clamping fasteners reduce setup times and boost productivity.

IMAO's quick release fasteners are available in a variety of clamping styles to suit your specific needs, including quarter turn fasteners, ball locking fasteners and pin holding fasteners.

Product Video

Lineup

Feature

Quick & Easy Locking with No Tool!

Just turning a knob or pushing a button completes the clamping and unclamping.

Tool-less locking with One Touch Fasteners eliminate the time required to tighten screws and nuts as with conventional methods.

Secure Clamping with Cam Locking / Ball Locking Mechanism!

The mechanical design securely clamps and holds the plates, providing more than just a locking function.

Constant spring clamping force provides error-free locking without over- or under-tightening.

Cam Locking

Cam locking fastener has high clamping force generated by the compressed spring.

Ball Locking

Ball locking fastener holds the plates with balls pushed out by the wedge to resist tensile forces.

Reliable Operation

Quarter-turn fasteners have ON and OFF marks, and clamping / unclamping is easily identified by the position of the knob.

Ball-lock fasteners clamp the part when the button is released, preventing accidental release.

Application

IMAO's quick release fasteners provide a changeover solution for inspection, packaging and printing processes in many industries, including food & beverage, pharmaceutical, electronics and automotive.

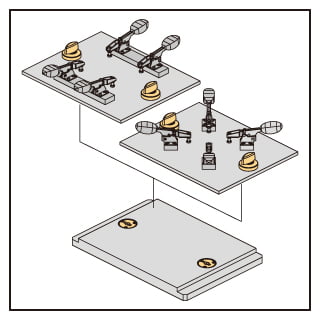

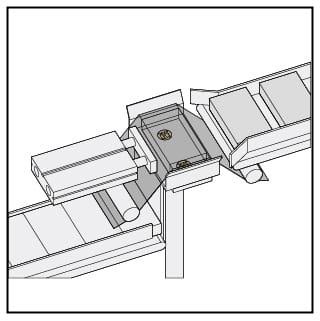

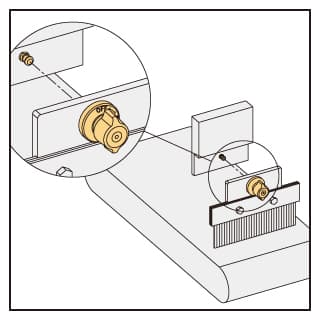

Tool-less Quarter Turn fasteners facilitate frequent assembly and disassembly of fixtures for electronic components.

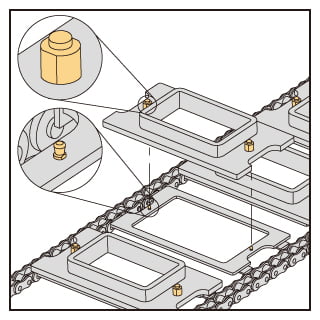

Fixture replacement operations on automated production machines were simplified with Button-Locking Pins.

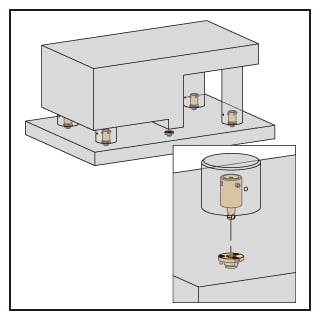

Knob Locking Pins provide quick and secure locking of the top plate, resulting in a safe and operator-friendly assembly line.

Product Review

Pipeline Design & Engineering in the United States posted a review on our Quarter Turn Fasteners.

Read the Quarter Turn Fasteners Review at Pipeline"Our mission statement here at Pipeline is to build equipment that R&D and manufacturing teams LOVE to use. One of the ways we do that is by using hardware that operators enjoy interacting with, like these quarter turn fasteners. We’ve used them for years and continue to do so not just because we like them, but because our customers love using them."

Visit the Pipeline Design & Engineering website for test fixture design

Case Study

CASE 1 Quarter Turn Fastener reduced fixture changeover time by half!

Toyokawa Engineering manufactures testing equipment for automotive parts and they use IMAO's Quarter Turn Fasteners on the fixtures in their equipment. They designed the fixture to be able to hold several workpieces at a time to fit the user's needs.

Setups for changing fixture parts come out every changeover depending on workpieces. The user required Toyokawa the swift changeovers of fixtures they do over 2 times a day. That's why Toyokawa decided to use IMAO's Quarter Turn Fasteners that shorten the setup time by clamping with just a 90 degrees turn of the knob.

In the previous testing equipment, the user fixed the parts with screws and knobs and it took more than 1 minute for changeover. With Quarter Turn Fasteners, changeover of fixture takes only 30 seconds.

Toyokawa highly esteems the quick & easy operation of IMAO's tool-less clamps, wide variation of line ups and their ready availability of IMAO's standard products as a manufacturer of standard machine elements. Toyokawa will keep using Quarter Turn Fasteners for their equipment in the future.

CASE 2 Quick & easy changeover in injection molding machine!

Panasonic Eco Solutions Electrical Construction Materials Mie Co., Ltd. manufactures intercom and fire alarm for home and they use IMAO's Quarter Turn Fasteners on injection molding line for the resin products. They cut the resin burr on back of the post-molded products by a nipper.

Setups for changing the nipper and its position come out every mold change because the position of the burr is different product by product. In the previous line, they used the general-purpose nipper units for all products and it took more than 15 minutes to loosen screws, change nippers and adjust positions. They needed to change the mold more than 50 times per month for some machines.

They decided to use dedicated nipper units for each product and clamp the units with Quarter Turn Fasteners to reduce machine downtime and set-up time. As a result, the changeover of units takes only 1 minute with One-touch fasteners, Quarter Turn Fasteners. Furthermore, the visible clamping and unclamping states by the position of the knob increased safety on their plant.

They will continue to improve production system by shortening the time for operation and changeover.

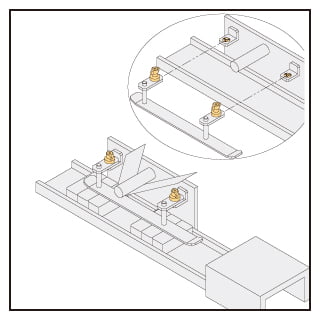

CASE 3 Quick release fasteners simplified assembly machine set ups!

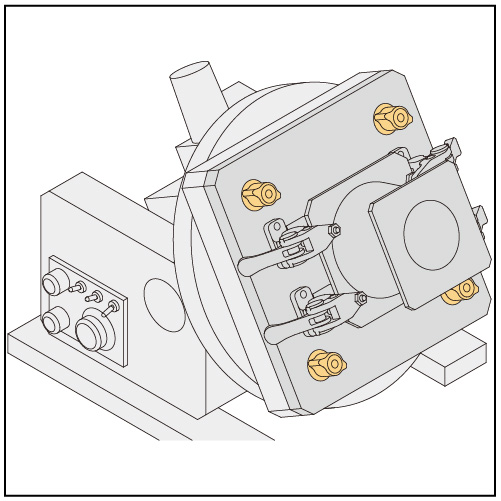

Iwata Mfg, Co., Ltd. manufactures machine components such as set collars and sensor brackets and they use IMAO's Ball-Lock Clamps and Button-Locking Pins to replace fixtures of automated production machines to assemble screws to the machinery parts body (hereinafter called "workpiece").

Previously, this work was done by a person but because of the high labor costs and the worker's mental burden for continuing simple tasks, they designed their own automated machine for purpose of reducing costs and mechanization of the simple work. This application requires "changeovers" which replace various fixtures depending on the workpiece around 10 times a day since this machine produces many products with different shapes and sizes, so they decided to use IMAO's One-Touch Fasteners to reduce the workloads.

In the process of setting the workpiece that was placed in a free direction to the right position, they clamp the workpiece from either side using an air cylinder with the plastic pad and adjust it by rotating. They use Ball-lock Clamps to fix the pad to replace 11 types of plastic pads depending on the form and size of the workpiece.

In another process of assembling screws to the workpiece, depending on the screw size, there are 5 kinds of holders for carrying screws and guides for preventing screws from dropping, and they can be quickly replaced by using the Button-Locking Pins. These quick release fasteners only require inserting the pin or pushing the button, so the changeover can be completed easily and in a short time.

The easy changeover process also reduces the machine operator's workload, as there are many parts that need to be replaced in a single changeover. They will keep continuing the development of automated machines that allow quick and easy changeovers to reduce the costs and the workloads.

CASE 4 Standardized quick release fasteners cut fixture costs by 70% and eliminated fixture maintenance!

Cosel Co., Ltd. manufactures "switching power supplies" that are indispensable for electronic products and they use IMAO's Quarter Turn Fasteners on assembly fixtures. They set the electronic substrate on the base plate and put the resin case. Set the clamping plate on the base plate, clamp, pour silicone rubber, and then do heat hardened treatment. They use Quarter Turn Fasteners when fixing the resin case with the clamping plate.

They used to use self-produced clamps, so a lot of cost and production time was required. In addition, they often stopped the production line for repairing the damaged clamps due to the loosening screws caused by heat hardening distention. A total of 80 fixtures are used per the assemble product in their production line, so they decided to use Quarter Turn Fasteners to achieve cost reduction and maintenance-free of the fixtures.

Furthermore, the tool-less and quick clamping Quarter Turn Fasteners were perfect for the workability since they produce approx. 200 products per day. By using Quarter Turn Fasteners, they succeeded in not only reducing the fixture cost by 70% but also have been using more than 2 years without any maintenance that previously needed once a week.

Cosel who has achieved great success by standardizing the clamps will positively keep using IMAO's One-Touch Fasteners for the ones needing quick clamping.

CASE 5 Button-Locking Pin assisted easy operation on laboratory device!

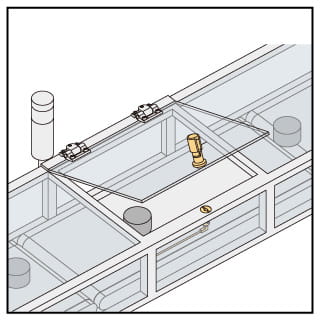

BioChromato designs and manufactures analyzers and evaporators for the Institute of Physical and Chemical Research. They use two types of IMAO's One Touch Fasteners on the evaporator which extracts particular solvent from the sample liquid.

Multiple vials with liquid are set in the holder to evaporate, and the vial holder is removed from the evaporator after evaporation, but the vial holder reaches high temperatures up to 100°C. That's why they use Button-Locking Pins for a detachable knob. Finger-operative shape and ball lock mechanism enable quick and secure changeover operation of the vial holder.

In addition, they use IMAO's Quarter Turn Fasteners to fix the plug holder that plugs into whole vials at once. Just a quarter turn of the knob enables locking/unlocking the plug holder and allows easy changeover.

The vial holders should be replaced after each experiment and the plug holders should be replaced every time the size of the vial changes, so customers of BioChromato are satisfied with one-touch changeover.

CASE 6 Quarter Turn Fastener provided quick and reliable fixture changing!

TGK develops control devices for automobiles worldwide and they use IMAO's Quarter Turn Fasteners on assembly fixtures for motor actuators.

In the process of assembling the bracket to the actuator, they use four types of dedicated fixtures. The operator needs to change the fixtures every time the actuator to be assembled changes. They used to clamp the fixtures with wing screws, but it was not only troublesome to turn the screws many times, but also time-consuming to find the removed screws when they were lost.

This led them to search for a better way to clamp the fixtures as the operators requested for improvement, and they decided to use IMAO's Quarter Turn Fasteners. One touch operation of Quarter Turn Fasteners provides quick and easy fixture changing and ON/OFF marking improves the reliability of the operation, so the operators are satisfied with IMAO's quick fasteners.

TGK plans to use IMAO's quick release fasteners in their new assembly lines in order to shorten the setup time and simplify the changeover.

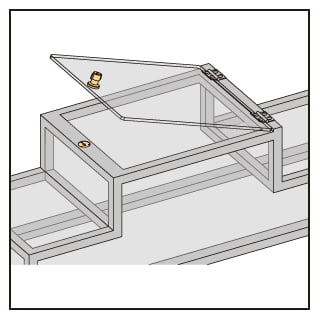

CASE 7 Safe and ergonomic production line is achieved by Quick Release Ball Locking Fasteners.

Endress+Hauser designs and manufactures industrial tank gauges. They have succeeded in building an ergonomic production line to reduce the burden of workers and improve work efficiency by using Knob-Locking Pins on their assembly fixtures of tank gauges.

In each assembly process, workers needed to place a product weighing up to 50 kg on a workbench and look inside the product body to assemble the parts, which was a physical burden on the workers. To solve this problem, the company designed a line that the workpieces can be moved from one process to another on a cart, and the height of the top plate with the workpiece can be adjusted to a comfortable height for each worker by a lifting device provided at each process.

In this line, the top plate that holds the workpiece is removed from the cart and the height is adjusted by the lifting device, so they decided to use IMAO's Knob-Locking Pins to quickly and easily fix the top plate and cart. Knob-Locking Pins are the solution for them to fix the top plate quickly and securely with its one touch operation and high holding force by the ball lock mechanism.

Endress Hauser plans to continue building their production system using IMAO's One Touch Fasteners to improve productivity.

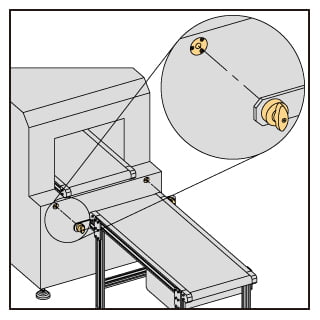

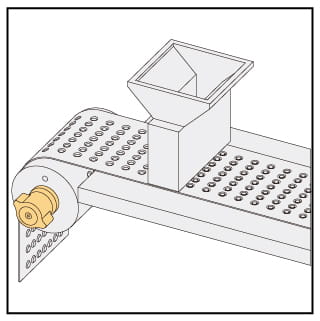

CASE 8 Quarter Turn Fasteners improved work efficiency on automated meat packaging machine!

Nantsune, a manufacturer of meat processing equipment, uses the Quarter Turn Fasteners to change the hands on their brand-new "Scorpion" an automated meat packaging machine. Scorpion automatically puts aligned slices of meat on food trays. The hands that carry the meat slices to the tray have to be changed at least once a day, when the shape of the meat slice is changed or for cleaning and maintenance.

Nantsune mostly used clamping knobs for such areas where removal and installation were required, however, the problem was that the operators had difficulties operating the knob. Each operator tightened it differently, and it was slippery with oil and water to operate. Some other problems were that operators could not visually check for proper tightening, loosening could occur due to under-tightening and it had no positioning function.

They solved these problems by using the Quarter Turn Fasteners, which provide constant clamping force with just a 90-degree turn of the knob. It also made it easier to check that the fastener was secured with the ON/OFF indicator. The repeatability of Quarter Turn Fasteners met the requirements for the machine hand changeover.

The work efficiency of the changeover was greatly improved by the one-touch operation of Quarter Turn Fasteners. Their equipment, "Scorpion" is highly appreciated by the users, and the one-touch operation also contributes to this positive appreciation.

Lineup and Application Example

QUARTER TURN CLAMPS

- Cam & spring clamping

- ON / OFF indicator for safety

- Available in stainless steel

-

Clamping Force(N) 60, 90 Holding Force(N) 60, 90

RETRACTABLE QUARTER TURN CLAMPS

- The shank retracts to enable slide or door applications

- Cam & spring clamping

- ON / OFF indicator for safety

- Available in stainless steel

-

Clamping Force(N) 60, 90 Holding Force(N) 60, 90

HEAVY DUTY QUARTER TURN CLAMPS

- Higher clamping force

- ON / OFF indicator for safety

-

Clamping Force(N) 250, 400 Holding Force(N) 250, 400

RETRACTABLE HEAVY DUTY QUARTER TURN CLAMPS

- The shank retracts to enable slide or door applications

- Higher clamping force

- ON / OFF indicator for safety

-

Clamping Force(N) 250, 400 Holding Force(N) 250, 400

FLAT QUARTER TURN CLAMPS

- Flat design ensures no interference

- ON / OFF indicator for safety

- Made of stainless steel

-

Clamping Force(N) 30, 60 Holding Force(N) 30, 60

KNOB-LOCKING PINS

- Clamp action sensing

- Ball lock clamping

- ON / OFF indicator for safety

- Available in stainless steel

-

Clamping Force(N) 30, 50 Holding Force(N) 90, 150

RETRACTABLE KNOB-LOCKING PINS

- The shank retracts to enable slide or door applications

- Ball lock clamping

- Clamp action sensing

- ON / OFF indicator for safety

- Made of stainless steel

-

Clamping Force(N) 30, 50 Holding Force(N) 90, 150

HEAVY DUTY KNOB-LOCKING PINS

- The highest clamping force & holding force

- ON / OFF indicator for safety

-

Clamping Force(N) 1000, 2000 Holding Force(N) 2500, 5000

RETRACTABLE HEAVY DUTY KNOB-LOCKING PINS

- The shank retracts to enable slide or door applications

- The highest clamping force & holding force

- ON / OFF indicator for safety

-

Clamping Force(N) 1000, 2000 Holding Force(N) 2500, 5000

PIN HOLDING CLAMPS

- Suitable for space-saving application

- Ball lock clamping

- Available in stainless steel

-

Clamping Force(N) 7,9 Holding Force(N) 110, 150

HEAVY DUTY PIN HOLDING CLAMPS

- Suitable for space-saving application

- Higher clamping force

- Available in stainless steel

-

Clamping Force(N) 150, 250 Holding Force(N) 450, 750

SNAP-IN CLAMPS

- Quick & easy snap-in operation

- Suitable for space-saving application

- Ball lock clamping

- Made of stainless steel

-

Clamping Force(N) 6 Holding Force(N) 100

BUTTON-LOCKING PINS

- Secure locking upon releasing button

- Ball lock clamping

- Made of stainless steel

-

Clamping Force(N) 30, 50 Holding Force(N) 90, 150

HOLE HOLDING CLAMPS

- No need for receptacle

- Secure locking upon releasing button

- Made of stainless steel

-

Clamping Force(N) 3, 6 Holding Force(N) 30, 60

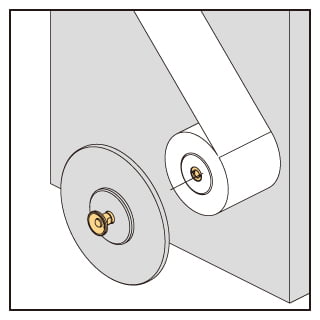

SHAFT COUPLING CLAMPS

- Multipurpose coupling element

- Cam & spring clamping

- Easy to clamp/unclamp by turning 90°

-

Clamping Force(N) 90 Holding Force(N) 90

HEAVY DUTY SHAFT COUPLING CLAMPS

- Higher clamping force

- Multipurpose coupling element

- Easy to clamp/unclamp by turning 90°

-

Clamping Force(N) 400 Holding Force(N) 400

SHAFT COUPLING CLAMPS WITH SAFETY LOCK

- Safety lock for axial & rotational force

- Multipurpose coupling element

- Easy to clamp/unclamp by turning 90°

BALL-LOCK CLAMPS

- Compact & safety mechanical locking

- Safety lock type is available

-

Clamping Force(N) 7, 15

MAGNET-LOCK CLAMPS

- Compact & instant magnetic attachment

-

Clamping Force(N) 7

Precision Locating Fasteners

provide precise locating repeatability and heavy duty clamping force

ONE-TOUCH FLEX LOCATORS (Knob)

- Quarter turn clamping

- 0.01mm repeatability

- 600N clamping force

ONE-TOUCH FLEX LOCATORS (Handle)

- Quarter turn clamping

- 0.01mm repeatability

- 700N clamping force

ONE-TOUCH FLEX LOCATORS (Cam Handle)

- Vertical handle operation

- 0.008mm repeatability

- 1800N clamping force

ONE-TOUCH FLEX LOCATORS (Hexagon Head)

- 0.008mm repeatability

- 4500N clamping force

You may also like

Flex Locators

Mechanical clamping locators for quick change applications

Learn More about Flex Locators

Pneumatic Clamping Fasteners

Automated quick fasteners for machine changeover

Learn More about Pneumatic Clamping Fasteners

Pneumatic Flex Locators

Locating fasteners for machine changeover

Learn More about Pneumatic Flex Locators

One Touch Push Lock Clamps

Versatile quick locks for slide and angle adjustment

Learn More about One-Touch Push Lock Clamps